Why RL Consulting PLC Programming Company Solutions Fit Both New and Aging Machinery

A well-built control system only performs as well as the people who understand how machines think. Many facilities rely on specialists who can read older hardware, introduce modern logic, and stitch them together without disturbing production. That balance is the reason RL Consulting PLC programming solutions continue to serve both advanced lines and equipment that has been running for decades.

Expertise Across Multiple Legacy Allen-Bradley Platforms (e.g., PLC-5)

Legacy platforms still run critical processes in plants across the country, and they require programmers who understand their instruction sets, communication limits, and memory layouts. Teams familiar with aging Allen-Bradley PLC-5 hardware can diagnose issues, rewrite outdated routines, and extend system life without forcing a full replacement. RL Consulting PLC programming teams support legacy assets by applying skills built from years of working directly with classic modules and older industrial protocols.

That experience makes it possible to stabilize systems that newer engineers may find unfamiliar. Legacy processors often respond differently under load, and their firmware structures require an approach shaped by past field exposure. Specialists capable of supporting these units help companies avoid unnecessary shutdowns and shift upgrades to a schedule that fits production demands.

Knowledge of Modern Platforms like the ControlLogix Family

Modern Allen-Bradley architectures call for a different mindset. ControlLogix systems handle larger data structures, advanced motion, and broader communication channels, making them ideal for new builds. RL Consulting Rockwell Allen Bradley PLC expertise ensures these platforms are programmed with clean structure, efficient tags, and logic optimized for long-term reliability.

ControlLogix installations also open opportunities for improved diagnostics and flexible expansion. Plants adopting these systems appreciate how long-term maintenance becomes easier when code is organized well from the start. Technicians who understand the architecture’s strengths can design RL Consulting custom PLC solutions that enhance speed, accuracy, and equipment consistency.

Team Members Having Extensive Actual Plant and Project Experience

Years working inside real production environments build instincts that classroom training cannot. Engineers who have stood beside conveyors, mixers, presses, and packaging lines understand how a control change affects the operator on the floor. RL Consulting control system integrators rely on these backgrounds to create programs that consider safety, cycle timing, and equipment wear.

Each project benefits from this practical understanding. Field-seasoned programmers anticipate mechanical lag, sensor placement issues, and how human operators interact with machine states. That awareness leads to logic that supports real-world workflow instead of relying solely on theoretical design.

A Vision Focused on Providing the Best Detailed Solution for Specific Needs

Facilities rarely share identical requirements, even when equipment appears similar. A solution tailored to one machine may not suit another running a slightly different recipe or packaging format. RL Consulting PLC programming company specialists build systems with attention to specific operational requirements rather than forcing a one-size approach.

This focus allows control strategies to match the rhythm and purpose of the machinery. Engineers can tune sequence timing, interlock behavior, alarms, and reporting to match what the process actually needs. The result is a clearer, more dependable control environment that operators trust.

Designing Systems That Are Inherently Adaptable to Future Upgrades

Expandable design reduces the stress associated with future improvements. Systems built with modular structures and organized data sets can welcome new drives, sensors, or process stages without rewriting the entire logic base. RL Consulting PLC programming structures often include forward-thinking design that leaves space for new features.

Equipment longevity depends on planning ahead. Plants adopting adaptable systems avoid costly rewrites later, because foundational logic already supports structured growth. This approach works well for facilities balancing new additions with older machinery upgrades.

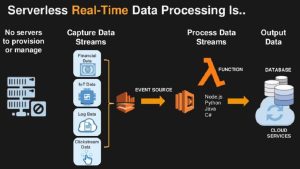

Ensuring Smooth Integration of Diverse Fieldbus Communications

Factories use multiple communication protocols, and connecting them without interference demands careful planning. Fieldbus networks such as DeviceNet, EtherNet/IP, Profibus, or older serial systems each carry unique timing rules and data exchange patterns. RL Consulting custom PLC integration ensures these networks coexist smoothly.

Different communication layers influence how machines respond to commands, alarms, and feedback. Skilled integrators know how to map, filter, and coordinate data so information flows consistently across the plant. This stability allows mixed generations of equipment to behave as a unified system.

Ability to Modernize Old Operator Interfaces to New HMI Systems

Operator interfaces reveal how well a system communicates essential information. Older HMI panels may limit message clarity, diagnostic detail, or navigation options. Updating them to new platforms improves usability and reduces troubleshooting time. RL Consulting Rockwell Allen Bradley PLC experience supports conversions from outdated terminals to modern graphic-based HMIs.

Each migration must respect how operators already use the machine. New screens can introduce better alarms, clearer status indicators, and improved process visualization while still retaining the logic flow users rely on. Plants gain a refreshed interface without sacrificing familiarity.

Integrating Current Technologies While Respecting Existing Infrastructure Constraints

Facilities cannot always overhaul entire production lines, yet they still need features like advanced sensing, analytics, and updated control strategies. Integration specialists help blend new technologies with older infrastructure without stressing power supplies, communication networks, or timing tolerances. RL Consulting provides this balance by designing additions that operate within established system limitations. Upgrades that fit seamlessly extend equipment life, reduce downtime, and open the door to gradual modernization. RL Consulting supports transitions with control and programming expertise shaped by decades of real industry work.

Post Comment