Not everything is the fault of diesel and NOx are formed in gasoline engines

For quite some time, but especially after the scandal Dieselgate Volkswagen, the “antidiésel” platforms out like mushrooms in autumn. After more than a decade overwhelmingly dominate the European market with nearly 70% of enrollments in some countries in the past year they are almost on par with the gasoline.

We seem to have gone to praise their good performance and low consumption to make them guilty of unbreathable air of our cities, the increase in cases of respiratory diseases, allergies …

Emissions from diesel engines are harmful to health is an undeniable fact, but is that current gasoline are not some sisters of charity precisely. As manufacturers have to extract more energy from every drop of fuel andreduce CO₂ emissions, other products appear in the gases of gasoline engines.

Previously, the only particles that emit these mechanics were small drops of gasoline that had not burned completely, but now that it has increased the pressure and temperature in the cylinders much to improve performance, also arise NOx feared and carcinogenic particles they.

The main difference between a gasoline engine and a diesel is that the former has to prepare an explosive mixture that is detonated by a spark, while in the second it does is burn a mixture due to heat and pressure that generated in the cylinder.

While gasoline blending should be stoichiometric to operate at relatively low pressures and when the spark, diesel ignites without the mixture is very accurate, in fact, diesel engines are always working with lean because, with an excess of air; why they do not need butterfly on the accelerator, a diesel engine always sucked all the air is able to enter their cylinders.

This basic difference in operation that produces diesel engines generate more NOx – between 3 and 10 times more – and more soot particles, but is that the search for higher yields and more energy from every drop of fuel, gasoline engines operate slowly a manner similar to diesel. To understand this, let’s see first what we mean with NOx.

What are NOx?

A group of chemical compounds which are nitrogen oxides are known as NOx. Both oxygen and nitrogen are harmless gases that are present in the air we breathe, the problem is when combined.

Depending on the chemical reaction in which oxygen molecules come together and nitrogen may arise several compounds N₂O, N₂O₃, NO₂, NO, N₂O₅ … All these compounds are included within the NOx.

In combustion engines, most NOx produced are actually nitrogen dioxide (NO₂) which is a very dangerous gas for health. Plus it is irritating in itself, when combined with hydrogen (which is also present in the air and water of our cells) is transformed into nitric acid, and breathe acid is not good.

What are the particles emitted by engines?

If the chemical reactions that take place in the cylinders were perfect, the only thing that should be generated by burning a hydrocarbon mixed with air should be water and CO₂. Unfortunately, in nature there are no perfect reactions, just as there is no perpetual motion.

In the combustion in the cylinders are still some fuel droplets that fail to burn completely, and other products that do not react in the process (sulfur fuel gases in the air , oil residues of engine lubrication. ..).

The high temperatures that are reached in the cylinders make the particles become ash are propelled by the exhaust pipe. These particles are very small enough to get into our body and adhere to our cells that may absorb and cause mutations in them, i.e. they are highly carcinogenic.

To avoid this, as diesel engines are the most solid particles emitted it is mandatory for years now the incorporate a particulate filter, charged with catching them. Gasoline engines did not generate many particles practically any in the past but as it has improved its performance and work pressures, increasingly emit more, although the authorities have not yet legislated anything about it.

How NOx and particulates produced in gasoline engines

To make it understandable I will use an example that more or less all have experienced in our lives, prepare one colacao.

Surely you’ve noticed that it is easier to dilute cocoa hot milk when it is cold. The temperature is an important factor when making a mixing and chemical reactions. If the temperature of the milk is not adequate or we spent with cocoa, they will be smooth. Making the perfect mix without lumps requires that milk has an appropriate, remove temperature for a sufficient time and not spend in the proportions.

If there is little cocoa and a lot of milk (lean) that does not know anything. If we spend with cocoa it becomes a brick unpalatable. If we do not remove enough (if not give time to the chemical reaction occurs) or not heat the milk to the optimal temperature, instead of reacting whole milk with all the cocoa have parts milk unmixed clumps cocoa .

As with chemical reactions cylinder gasoline engines passes something very similar. To the reaction is perfect (for all gasoline mix with all the air), the proportion of air and fuel must be perfect, that is, one mole of fuel molecules have to react with one mole of air molecules. The atomic weight of the gas molecules is 14 times larger than that of air, so to react the same number of molecules of each other. In this case the ratio is 14 to 1.

Diesel engines, however, do not work with a stoichiometric mixture, always operate with excess air , thus consuming less. The evolution of petrol engines is to try to mimic the performance of diesel to improve their performance. Indeed, direct injection engines gasoline current work as a lean – burn diesel when we go to tip gas (llaneando) and pass by with stoichiometric mixture when accelerated.

To make the mixture explodes when running low on fuel, which is done is to increase the compression in the cylinders and concentrate gasoline near the spark plug, so that around the spark we have a stoichiometric mixture itself is flammable and certain amount of energy.

You may also like to read another article on AnarchismToday: Living in the suburbs, have an electric car and be happy life

However, in the cylinder, there is an excess of air that fails to react completely with the fuel, but as high temperatures are reached due to high compression and energy of the explosion begin to react some components of the air, if they had another partner with whom to relate would not.

When the engine works in stratified system (it is named for the lean because it is stratified near the spark plug so that there is richer, as I said before), the molecules of the intake air that find no fuel with which to react, as they are under a lot of pressure and temperature they begin to become intimate with bad company and we have the mess father.

Yes, we have improved engine performance and took more energy from every drop of gasoline, but as we have milk at the ideal temperature (too hot), and the proportions are perfect (there is little cacao), the result is lumps (NOx and other impurities).

Heretofore, diesel engines were more NOx and byproducts generated in the combustion, but modern gasoline engines are true machines produce very harmful “products”. Unfortunately, seeking to reduce fuel consumption and emissions of CO and CO₂, we finish producing other molecules that are most harmful, besides increasingly fine ash that can adhere to our cells causing cancer.

How to remove NOx and particulates

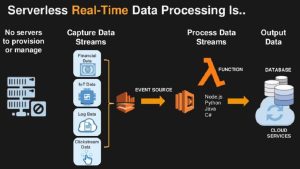

We see that both particles and NOx, are produced by a chemical reaction. The same is generated, they can be eliminar.Basta to introduce a new “laboratory” in the car’s engine to be responsible for causing new chemical reactions that transform these gases and other products.

The good news is that there is a solution to this problem, the trouble is that cost money (less than 18 – inch wheels, but not molan both) and are likely to lead to a malfunction. Moreover, as far authorities have not paid attention to this problem, gasoline engines are spared the severe anti particles from diesel standards, because until now they were out of the controversy.

Volkswagen -very timely after the bad reputation that has been earned by cheating on their emissions – has just announced that it will be the first brand to introduce particulate filters in the exhaust systems of gasoline engines.

To remove NOx solution is a special catalyst. In the case of cars, the catalyst is a ceramic piece with much exposed to the passage of gases (about one hectare) but is “bent” as many times as to fit into a kind of tube about 15 cm surface in diameter and 30 cm long.

This ceramic surface is coated with precious metals that make the same effect as alcohol in a nightclub at 5 in the morning. That boy or that girl who a few hours before you would not have approached or with a stick. As with the exhaust the same.

Molecules NOx remains unburned fuel, etc., by contact with these metals and the temperature that accumulates in the catalyst begin to interact with oxygen and other gases present in the exhaust and become other molecules that they are not harmful, mainly N₂, O₂ and CO₂. So that there is enough “material” in the exhaust system and to transform all NOx into other molecules, it is injected into the exhaust system urea. AdBlue is your business name, sounds finer than “diluted urine in water”, but it is just that: urine.

The particles, as are a solid product, it is more difficult to make them react, so what you do is catch them on a filter and when it is about to become saturated, the temperature rises in the filter to incinerate completely .

What problems do GPF and NOx catalysts?

The main problem with these two devices is that they cost money. Especially the NOx catalyst exceeds 2,000 euros the amount of precious metals that has inside, such as platinum or palladium. The particulate filter, however, is much cheaper, the order of 150 euros for the manufacturer.

The next problem is that these elements are integrated in the exhaust gas stream, which reduces engine power and increases fuel consumption. Luckily design has greatly improved and increasingly absorbs less energy in the gas flow.

However, for the car owner the biggest drawback is that these devices are susceptible to breakdowns, something they know very well those with a post-2004 diesel car, the year in which they began to install these filters.

In these cases the engine fails to achieve sufficient temperature and do the necessary revolutions turn to that in the exhaust gases have enough energy to take place chemical processes needed.

Even a decade or so, diesel engines were reputed to be “tougher” than gasoline does. Indeed, its construction is more robust. However, the incorporation of these anti particulate filters, complex systems of high pressure injection (over 2,000 bar) and overfeeding with turbos the prices increased and reduced reliability, to the point that, to date today, a gasoline engine is less problematic than a diesel.

Indirect injection engines working with gasoline fuel at a pressure of 3 or 4 bar .Today’s engines are all above 200 bar, even reach 400 bar. If ever you have wet hands with diesel at a gas station, you know that diesel has an oily feel. Indeed, the diesel has certain lubricating properties. However, gasoline evaporates quickly and leaves no residue. Its lubricating capacity is minimal. This makes both the high-pressure pumps as modern gasoline injectors are subjected to a fairly high erosion and are becoming more frequent their faults.

In conclusion, we must assume that if we want efficient engines from the thermodynamic point of view which have power and spend little, to contender- and that are as safe for the environment and living organisms, the engines will be increasingly complicated. Be more complex mean that it is more expensive and also more ballots to suffer damage.

In any case, always loses the same: all. If these catalysts and these filters will end up unable to breathe or having to prohibit the use of the car is not incorporated, and if we incorporate them to bear the cost.

Post Comment