What Should Analytics Be Tracked in Manufacturing?

So, what analytics should be tracked in manufacturing? Manufacturing businesses collect a lot of data every day, but it can take time to extract meaningful insights from it. That’s where manufacturing analytics comes in.

These tools plug into all aspects of manufacturing operations, drawing vital data in real-time and analyzing it to provide actionable insights. This helps manufacturers make smarter operations decisions, leading to better overall business performance.

Overall Equipment Effectiveness (OEE)

Overall Equipment Effectiveness (OEE) is a key metric that allows companies to identify what percentage of production time is productive while also giving them a standardized gauge for tracking progress. The metric combines three factors: availability, performance, and quality.

Availability refers to how often a machine works when needed, including scheduled and unplanned downtime. An asset with an OEE of 100% means that it always operates at the desired efficiency level and produces good quality products.

Performance is the speed at which an asset produces a product. This can be calculated from ideal cycle time data established manually or from the manufacturer.

Quality is the number of high-quality items an asset produces at any given time. This metric is crucial because it helps manufacturers identify issues that can lead to scrap or reworked parts.

OEE aims to improve manufacturing processes by identifying weak points and inefficiencies. However, managers should not be solely focused on boosting OEE scores. Instead, they should focus on addressing problems that will keep them from delivering value to customers.

Machine Performance

Machine performance metrics should be tracked to ensure that machines run at rated speed and produce quality parts. These include availability scores, quality scores, and overall equipment effectiveness (OEE).

To calculate OEE, divide the operating time of a machine by its planned production time to find its available productivity rate. Ideally, this should be 100 percent.

It is a good idea to track OEE regularly and assess trends to identify areas where productivity could be optimized. Having a target OEE allows plant managers to see the potential return on investment for individual pieces of equipment and the entire factory.

When analyzing production efficiency, manufacturers should also consider the role of their machine operators. With a data-rich machine connectivity platform, operators can track their productivity in real-time.

Manufacturers can then leverage this information to improve their processes and boost output. For example, suppose low productivity is caused by a lack of raw materials or a delay in receiving them from the warehouse. In that case, the data can help them increase their output by making minor adjustments.

Throughput

Production throughput is one of the most important metrics in a manufacturing company. It helps enhance operational efficiency and order fulfillment cycle time. It also plays a significant role in customer satisfaction and brand reputation.

Throughput is the number of raw materials and work-in-process that are transformed into finished goods within a specified time frame. This number shows the capacity of a machine or line to produce high-quality products and meet customer demand.

A company should look for any bottlenecks affecting the production process to increase manufacturing throughput. Once these problems are identified, company managers can use various techniques to improve productivity.

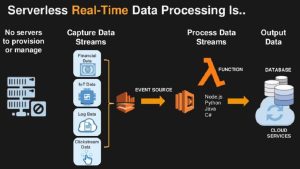

The most common method involves technologically facilitated real-time monitoring to spot slowdowns in production operations. Other methods include implementing checklists to help eliminate errors and speed up production processes.

To keep up with the competition, a manufacturer needs to ensure that its production lines produce quality goods efficiently. The throughput metric is essential to this goal, as it helps manufacturers meet their target quotas and avoid losing customers.

Customer Rejects

Rejection is a part of life, whether from a customer, friend, or romantic partner. It can be a painful experience and an indicator that something is wrong in your business, but it’s not impossible to overcome if you know how.

Entrepreneurs who face rejection can react in one of two ways: destructively or constructively. It’s important to find the right balance between coping with rejection and moving forward, so getting feedback from your customers and taking steps to address the underlying issues is best.

Productivity metrics help manufacturers identify bottlenecks in their production lines or solve problems to increase efficiency. These include Overall Equipment Effectiveness (OEE), machine run-plus downtime, and throughput.

In addition to machine data, manufacturers should also track order data to ensure that items ordered are fulfilled within the required timeframe. This includes the number of rejected orders, as well as those that are still in progress.

Rejections may be based on customers’ unmet needs, such as quality or price. However, they can also be caused by insufficient demand for a product or service. If this is the case, you need to reevaluate your business and ensure that you have the correct marketing strategy to meet consumer demands.

Lead Time to Customer

As a business, you need to know what analytics to track to meet your goals and objectives. The key is to choose specific, measurable, actionable, realistic, and time-based metrics.

One of the most important manufacturing KPIs is lead time. This metric determines how long it takes to get inventory on hand, process an order or manufacture and deliver a good.

The length of lead time can vary between industries, so it is crucial to accurately calculate and account for this metric. Various factors can affect lead time, including transportation issues, labor shortages, and raw materials.

Shorter lead times can improve customer satisfaction and increase sales. In addition, products with faster turnaround windows run a lower risk of obsolescence.

Several ways to reduce lead time include monitoring transportation methods, incentivizing better service, and improving inventory management. Keeping tabs on these factors will ensure that your customers receive their goods on time and are satisfied with their experience.

Post Comment